Self-guided, intelligent decision-support systems through DTL inside DIGEST

In the context of the DIGEST Project WP2, the UPM research team is elaborating a study that significantly advances the understanding and application of AI-driven quality inspection systems under the highly restrictive conditions that characterize industrial environments. The research delves deeply into the challenging domain of galvanized steel coil inspection, where data scarcity, extreme class imbalance, and constrained augmentation possibilities complicate the deployment of reliable machine learning models. These challenges mirror the real-world limitations that DIGEST WP2 seeks to address through its focus on enhancing industrial digitalization and decision support mechanisms.

Technically, this work demonstrates the efficacy of Deep Transfer Learning (DTL) strategies, particularly through the fine-tuning of YOLO models pre-trained on vast generic datasets. By leveraging the feature extraction capabilities of YOLO, the research overcomes the scarcity of defective samples, a common issue in quality control processes, by retaining generalizable knowledge from large-scale datasets while carefully adapting to the specific patterns of zinc coating defects. This approach directly contributes to the DIGEST WP2 objectives by providing a scalable and computationally efficient solution that minimizes the dependency on costly and time-consuming data labeling efforts. Furthermore, the work offers practical insights into the optimal configuration of transfer learning models, including the number of frozen layers and the application of class-weighted loss functions to combat severe data imbalance.

Complementing this, the study explores Contrastive Learning (CL) techniques through the development of a Siamese network architecture capable of learning robust similarity metrics for one-shot defect classification. Although the CL approach demonstrated conceptual strengths in handling limited data, the comparative analysis underlines that DTL offers superior performance in environments where augmentation is restricted by the need to preserve domain-specific spatial patterns. This finding is particularly relevant for DIGEST WP2, as it informs decision-making on model selection when deploying AI-based inspection solutions in industrial scenarios with similarly constrained data characteristics.

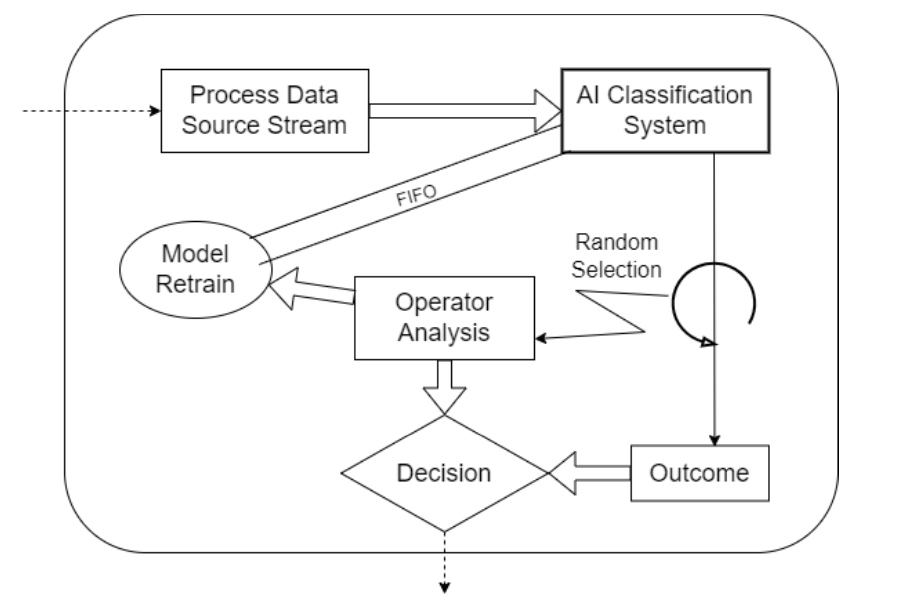

A further key contribution is the incorporation of a human-in-the-loop feedback mechanism, which embodies the principles of adaptive learning and continuous system improvement central to DIGEST WP2. The proposed framework allows for asynchronous feedback from human experts, enabling the dynamic refinement of AI models as new defect types emerge or production conditions evolve. This adaptive capability not only enhances the long-term reliability of the inspection system but also supports more resilient decision support infrastructures in line with the DIGEST Project’s vision for smart, data-driven manufacturing environments.

A distinctive and impactful contribution of this research, directly aligned with the innovation goals of the DIGEST Project WP2, is the development of an automated retraining framework that ensures sustained model performance through intelligent monitoring and adaptive learning cycles. In industrial environments where production conditions and defect patterns can change unpredictably, static AI models rapidly lose effectiveness. Recognizing this challenge, the proposed framework introduces a fully integrated pipeline capable of continuous performance evaluation and autonomous model improvement without requiring constant manual intervention.

At the core of this framework is a sophisticated monitoring system that tracks model performance in real time against key metrics such as accuracy, precision, recall, and F1-score, particularly focusing on the detection of rare but critical defect cases. When the system identifies that performance on recent production batches has fallen below a predefined threshold—such as an F1-score drop or excessive misclassification of defects—it automatically triggers a retraining process. This decision is grounded in empirical criteria rather than ad hoc human judgments, ensuring objectivity and consistency in model lifecycle management.

The retraining workflow leverages a combination of newly accumulated production data and expert feedback captured through a human-in-the-loop mechanism. This feedback loop ensures that the system not only adapts to gradual shifts in product characteristics but also rapidly incorporates knowledge about newly emerging defect types that were previously unseen. The retraining process itself is optimized to preserve computational efficiency, using strategies like selective fine-tuning of model layers and incremental learning techniques that minimize downtime and resource consumption.

Crucially, this framework embodies the DIGEST WP2 objective of fostering self-guided, intelligent decision-support systems in manufacturing environments. By embedding mechanisms for autonomous learning and performance optimization, the solution moves beyond traditional static inspection systems toward a truly adaptive, resilient, and future-proof industrial AI infrastructure. This level of automation not only reduces reliance on scarce data science expertise for ongoing maintenance but also ensures that deployed models remain aligned with evolving quality standards and production realities, ultimately driving greater operational efficiency and product quality in Industry 4.0 ecosystems.